Making Buildings Sustainable

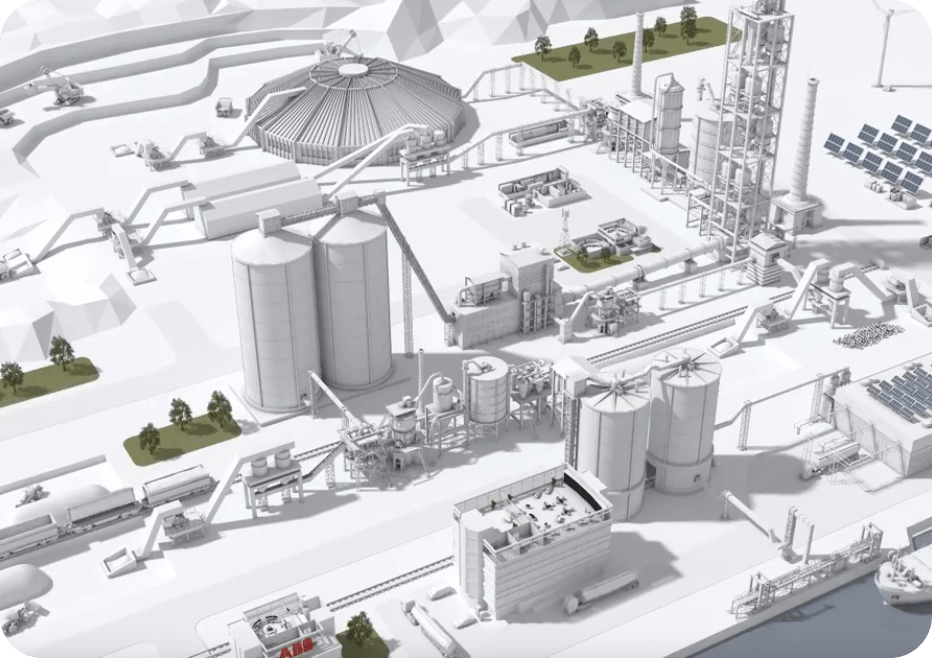

Precise Process Control: Utilizing real-time elemental analysis and dedicated cement control software can drive efficient bulk materials handling and blending via responsive automated controls.

Material Efficiency: Promoting material efficiency in construction by avoiding overdesign and maximizing the lifetimes of buildings and infrastructure can reduce cement demand.

Clinker Substitutes: Supplementary cementitious materials (SCMs) like calcined clays, burnt shale, and silica fume can replace clinker in cement, reducing the carbon footprint.

Sensors, AI, and Data Science: The impact of such concepts in concrete production has been profound. Our AI integration has improved both throughput and energy efficiency significantly, demonstrating its potential in optimizing cement production processes.

IFESTOS is a pioneering Carbon Capture project that not only seeks to propel TITAN Group’s decarbonization journey but also plays a pivotal role in expediting the sector’s green transition, and substantially contributing to promoting carbon capture technology throughout the continent.

The project involves the construction of a large-scale carbon capture facility at TITAN’s flagship Kamari plant near Athens, Greece. This facility will enable the decarbonization of cement manufacturing and the offering of innovative green building materials in TITAN’s markets. TITAN will be producing about 3 million tones/year of zero-carbon cement, to serve the growing needs for green construction in the metropolitan area of Athens and beyond. Kamari will be retrofitted with cutting-edge carbon capture technology, aiming to avoid over 1.9 million tons of CO₂ emissions yearly, potentially ranking it among Europe’s largest carbon capture facilities. This project will integrate with a broader ecosystem, uniting carbon capture with sea transportation and storage infrastructure.

The project involves the construction of a large-scale carbon capture facility at TITAN’s flagship Kamari plant near Athens, Greece. This facility will enable the decarbonization of cement manufacturing and the offering of innovative green building materials in TITAN’s markets. TITAN will be producing about 3 million tones/year of zero-carbon cement, to serve the growing needs for green construction in the metropolitan area of Athens and beyond. Kamari will be retrofitted with cutting-edge carbon capture technology, aiming to avoid over 1.9 million tons of CO₂ emissions yearly, potentially ranking it among Europe’s largest carbon capture facilities. This project will integrate with a broader ecosystem, uniting carbon capture with sea transportation and storage infrastructure.

20.227.227 tonnes C02 equivalent

31 December 2029

EUR 234,000,000

Cement Production is a resource-heavy process. Our latest discoveries and efforts have been concentrated in solidifying our production pipeline with better throughput and efficiency, where recycling waste and pre-existing material takes center stage in minimizing the ecological aspects of cement fabrication.

Concrete from demolished structures can be crushed and reused for road gravel, revetments, retaining walls, landscaping gravel, or as a raw material for new concrete. Large pieces can also be repurposed as bricks or slabs.

The cement value chain is well positioned to create closed loops, or automatically regulated systems, for carbon dioxide, materials and minerals, and energy. This entails circular economies, which are based on the principles of eliminating waste and pollution, circulating products and materials, and regenerating nature

HQ Address: Rr. Durrësit,

Pallati mbrapa Ring Center,(kati 1), 1014

Tiranë, Shqipëri